China National Heavy Duty Truck (CNHTC) is the largest truck manufacturer in China, producing a comprehensive range of vehicles for various industries. The chassis is a crucial component of a CNHTC truck, providing the foundation for the vehicle. In this article, we will discuss the key aspects of heavy truck chassis parts.

The Components of CNHTC Chassis

A CNHTC chassis is composed of various components working together to provide a stable and reliable foundation for the vehicle. Here are some of the essential components of a CNHTC chassis:

- Frame: The frame is the backbone of the chassis, providing the structure for the vehicle. CNHTC frames are typically made of high-strength steel and designed to provide maximum rigidity and durability.

- Suspension: The suspension system connects the wheels to the frame, absorbing shocks and providing a smooth ride. CNHTC suspension systems may include leaf springs, air suspension, or combination suspension systems.

- Brakes: The brakes are essential for stopping the vehicle and preventing accidents. CNHTC trucks may be equipped with hydraulic, air, or electric brake systems.

- Steering System: The steering system is responsible for controlling the direction of the vehicle. CNHTC trucks may be equipped with mechanical, hydraulic, or power steering systems.

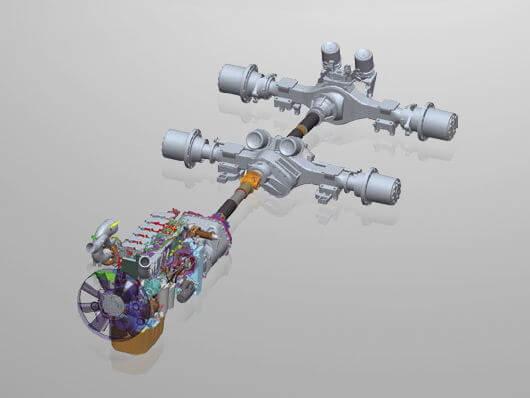

- Axles: The axles connect the wheels to the frame, providing support and transmitting power to the wheels. CNHTC trucks may be equipped with single, double, or tandem axles.

Types of CNHTC Chassis

CNHTC produces a wide range of chassis for various industries and applications. Here are some of the types of CNHTC chassis:

- Tipper Chassis: Tipper chassis are designed for transporting bulk materials such as sand, gravel, and construction waste.

- Tractor Chassis: Tractor chassis are designed for pulling heavy loads such as trailers and containers.

- Mixer Chassis: Mixer chassis are designed for transporting and mixing concrete.

- Cargo Chassis: Cargo chassis are designed for transporting goods and products in various industries.

Maintenance and Repairs

Maintaining and repairing a CNHTC chassis is essential for ensuring optimal performance, safety, and longevity. Here are some of the maintenance and repair tasks that a CNHTC chassis may require:

- Inspections: Regular inspections can reveal potential issues such as cracks, wear, and damage to the chassis components. Inspections may include visual inspections, fluid analysis, and computer diagnostics.

- Lubrication: Chassis components such as bearings and joints require proper lubrication to prevent wear and damage. Following the manufacturer’s recommended lubrication schedule is essential.

- Brake Maintenance: The brake system requires regular maintenance to ensure that it functions correctly and prevents accidents. Maintenance may include replacing brake pads, calipers, and brake fluid.

- Suspension Adjustment: The suspension system requires proper adjustment to ensure proper ride height and handling. Regular adjustment can prevent premature wear and damage to the suspension components.

CNHTC chassis is a critical component of the vehicle, providing the foundation for the vehicle and ensuring optimal performance, safety, and longevity. Understanding the components and types of CNHTC chassis, as well as the necessary maintenance and repairs, is essential for optimizing the vehicle’s performance and safety.

Maintenance and Repair Tips for CNHTC Truck Chassis

Sinotruks are widely used in various industries due to their reliability, durability, and high performance. Proper maintenance and repair of the truck chassis parts are crucial for ensuring the safety, efficiency, and longevity of the truck.

Regular Inspection of Chassis Components

To keep your CNHTC truck chassis in good condition, it is essential to conduct regular inspections of various components such as the frame, suspension, brakes, steering, and axles. Regular inspections can help detect issues early before they escalate and lead to significant damage to the chassis and the vehicle. Here are some components to inspect:

- Frame: Regularly inspect the chassis frame for cracks, wear and tear, corrosion, and damage due to exposure to harsh environments and heavy loads. Ensure the proper alignment of the frame to prevent uneven tire wear and improve vehicle handling.

- Suspension system: Inspect the suspension system for signs of damage, wear, and leaks. Check the condition of the shock absorbers, springs, and bushings. Adjust the suspension as required to maintain the proper ride height.

- Brakes: Inspect the braking system regularly for worn-out pads, rotors/drums, and fluid leaks. Replace worn-out brake pads immediately to avoid brake failure and increase the safety of the truck.

- Steering: Check the steering system for proper alignment, wear, and tear, and signs of leaks. Ensure that the power steering system is well lubricated and functioning correctly.

- Axles: Inspect the axle components for wear, leakage, and damage. Ensure that the axle gears and bearings are well lubricated and maintained. Properly align the axles to prevent uneven tire wear and improve handling.

Lubrication of Chassis Components

Lubrication is critical for maintaining the performance and longevity of chassis components, such as bearings, joints, suspension, and steering system. Proper lubrication ensures that the components operate smoothly, reduces friction and wear, and protects against corrosion and rust. Follow the manufacturer’s recommendations for lubrication and use the appropriate lubricants for each component.

Brake System Maintenance

The braking system is one of the most crucial systems in any vehicle, and proper maintenance is critical for safety and longevity. Here are important brake system maintenance tips:

- Brake Pads: Regularly inspect the brake pads for wear and replace them immediately if worn out. Worn-out brake pads can cause brake failure, leading to accidents.

- Brake Fluid: Regularly check the brake fluid level and replace it if contaminated or lower than the recommended level. Brake fluid absorbs moisture and can corrode the brake lines, leading to reduced performance and failure.

- Brake Calipers: Inspect the brake calipers for leaks, corrosion, or wear. Replace them if they are worn out or damaged as they can cause uneven braking and brake failure.

Suspension Adjustment and Repair

The suspension system is responsible for providing a smooth and comfortable ride, and proper adjustment and repair are critical for achieving this goal. Here are some tips for suspension adjustment and repair:

- Ride Height: Adjust the suspension system to maintain the proper ride height, ensuring that the vehicle does not bottom out or sway excessively.

- Shock Absorbers: Inspect the shock absorbers regularly and replace them if worn out. Worn-out shock absorbers can cause poor vehicle handling and may lead to accidents.

- Alignment: Properly align the suspension system to prevent uneven tire wear and improve handling.

Maintaining and repairing a CNHTC truck chassis is necessary for ensuring optimal performance, safety, and longevity. Regular inspections, lubrication, brake system maintenance, and suspension adjustment and repair are key maintenance and repair tasks necessary for achieving these goals. Proper maintenance and repair of the chassis can help to prolong the life of the vehicle, prevent accidents, minimize downtime, and reduce overall costs.