SEMA can feel like a sensory overload — a blur of roaring engines, flashing lights, and crowds all fighting to see the latest jaw-dropping builds. Amid that chaos, certain names stand out year after year — builders who don’t just show up, but set the standard. One of those names is Ringbrothers, a shop synonymous with precision, artistry, and muscle car perfection.

Their latest masterpiece, the Kingpin Ford Mustang, continues that legacy with a build that blends bold creativity with flawless execution. We caught up with Ryan Fielding, one of Ringbrothers’ master fabricators, and Jake Hodess, the proud owner of the Kingpin, to get an inside look at how this modern legend came to life — and to uncover some of the small but striking details that make it truly stand apart.

How The Project Started

Jake Hodess shared that the 1969 Mustang Mach 1, which would eventually transform into the Kingpin, had been in his possession for a few years before finding its way to the Ringbrothers workshop. He discovered the car in Florida — a bit rough around the edges, showing its age and past life, but still a solid foundation for something special.

After holding onto it for some time, Hodess began reaching out to custom shops to explore the idea of turning his Mustang into a full-blown build. When he connected with Ringbrothers, timing was on his side — the shop had an opening in their busy schedule, and that’s where the journey of Kingpin truly began.

Once the Mustang arrived at Ringbrothers, the build quickly turned into a true collaboration between the shop and Hodess. He came in with a few clear must-haves — the car needed to be black, equipped with a manual transmission, and fitted with a great sound system. Bright chrome? Absolutely not. He wanted a more refined look, something that exuded confidence without shouting for attention.

Hodess also envisioned an interior that felt elegant and timeless, describing it as “like a tuxedo” — sharp, sophisticated, and understated. The Ringbrothers team took that concept and ran with it, not just building the car, but giving it an identity. They christened it “Kingpin”, a name that perfectly balanced the car’s dual personality: menacing and powerful, yet classy and composed. Hodess loved it — and the transformation began.

No Detail Is Too Small For Ringbrothers

It’s clear that Ringbrothers took Hodess’ vision to heart — and then elevated it. The Kingpin wears a deep, glossy black paint job that looks like it could swallow light whole. Every trace of chrome or stainless trim from the original ’69 Mach 1 has been banished — grille, bumpers, window surrounds, all refinished in black to create a seamless, menacing look.

To break up the darkness just enough, the team added matte black racing stripes that run across the roof and trail down the sides into the rear vents — subtle, but undeniably purposeful.

What really sets the Kingpin apart, though, is how much of it has been handcrafted. Many of the parts that appear stock are, in fact, custom-built pieces, precisely fabricated by Ringbrothers. Even details that most people would never notice received the same attention. It’s that obsessive craftsmanship — hidden or not — that makes this build stand out in a sea of custom Mustangs.

Let’s start up front — the grille. According to Ryan Fielding, the fabricator behind much of the work, the team built it as a single solid piece, doing away with the factory grille’s awkward seam that broke up the front end’s flow. The result? A cleaner, more cohesive look that perfectly fits Kingpin’s sleek personality.

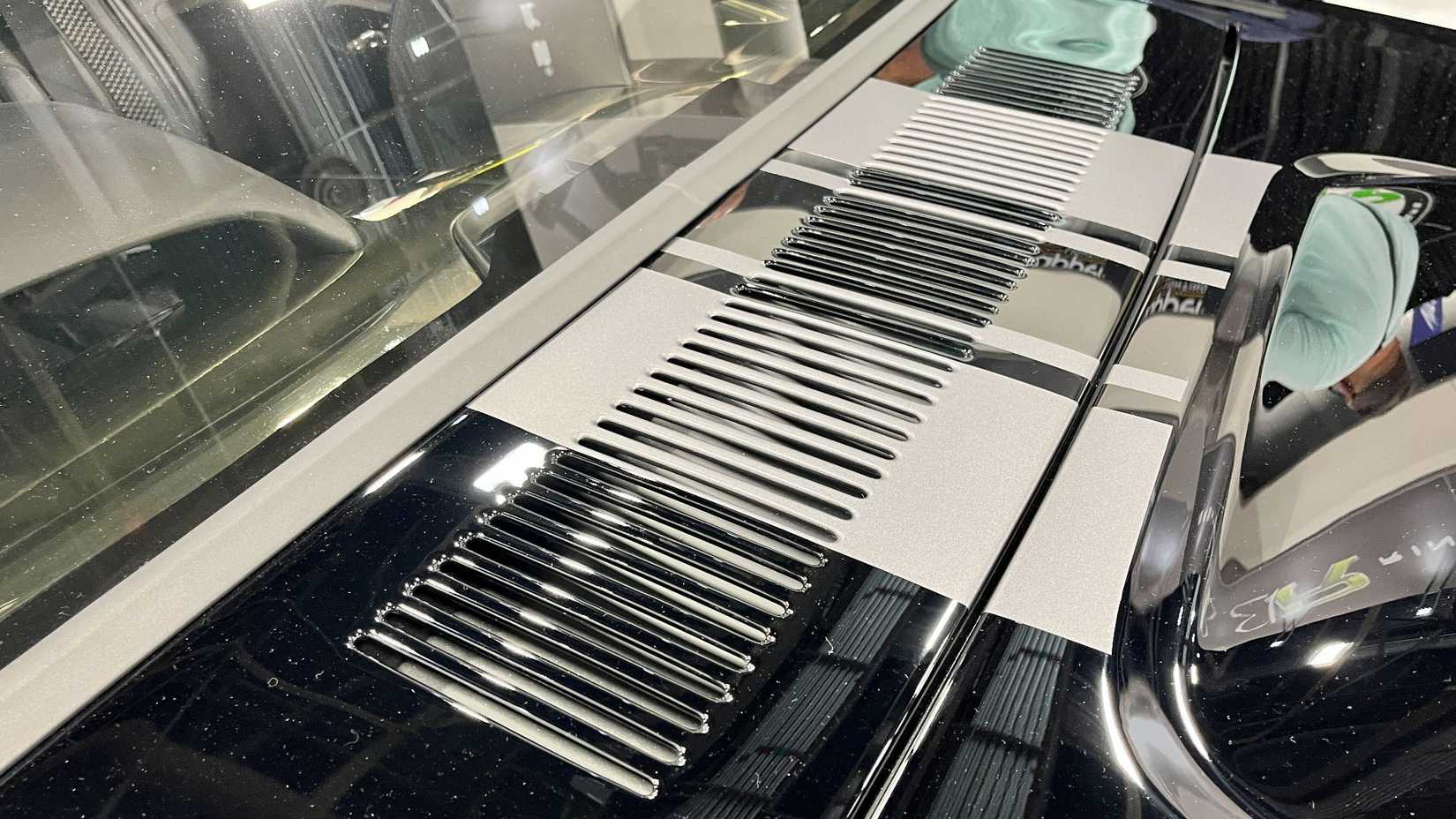

The same philosophy carried over to the cowl vents beneath the windshield. Ringbrothers wanted everything to look intentional — no clutter, no distractions. Since Hodess wasn’t planning on taking the car out for rainy Sunday cruises, the windshield wipers were deleted entirely to keep the design pure.

Normally, those wiper hinges would stick up like sore thumbs from the cowl area, so the team got creative. They sourced an extra cowl, then spliced in sections of venting until the entire piece featured evenly spaced openings from end to end. The result was subtle, but it made a huge difference — the kind of detail that separates a clean custom from a showstopper.

Another standout detail lies in the rear vents and taillight assembly, where Ringbrothers turned what was once purely cosmetic into something fully functional. On a stock ’69 Mustang Mach 1, those side intakes on the rear fenders were just for show — nice to look at, but useless in practice.

On Kingpin, though, they actually duct cool air straight to the rear brakes, helping manage heat during spirited driving. But Ringbrothers didn’t stop there. The team engineered additional air outlets that vent through the LED taillights themselves — a subtle yet brilliant touch that merges form and function seamlessly.

It’s one of those details you might miss at first glance, but once you notice it, you realize just how much thought went into every inch of this build.

The interior of Kingpin is just as fascinating as its exterior — a perfect blend of modern craftsmanship and classic design. According to Ryan Fielding, almost every component inside the cabin, aside from the seats and shifter, was 3D-printed. That includes the dashboard, grab handles, trim pieces, and even some of the smaller accents most people wouldn’t think twice about.

But Ringbrothers didn’t just print parts and call it a day. To match Hodess’ vision of a refined, tuxedo-like interior, certain pieces received a dark metallic finish with a subtle golden sheen. For that extra touch of artistry, the team enlisted a company that normally plates and finishes college football helmets — giving the car’s cabin a one-of-a-kind luster that’s both sleek and slightly dramatic.

3D printing wasn’t limited to the inside, either. You’ll find it throughout the car — from the hood scoop inserts to the steering wheel and fuel cap medallions. Interestingly, those medallions weren’t plastic at all; they were 3D-printed in metal, adding a tactile sense of quality that’s impossible to fake.

It’s the kind of craftsmanship that blends new-age technology with old-school flair — a perfect metaphor for Kingpin itself.

A build like Kingpin doesn’t happen overnight — and Ryan Fielding was upfront about that. He shared that the team logged roughly 5,500 hours into the project over the course of 18 months. That’s no small feat, but when you think about the level of craftsmanship and detail packed into this car, it’s pretty astonishing that Ringbrothers pulled it off in under two years.

When we caught up with Jake Hodess, it was clear just how much the car meant to him. And the timing couldn’t have been more special — the day of our conversation was also the first time he’d ever seen the completed Kingpin in person.

Imagine that moment: walking into SEMA, surrounded by the roar of cameras and the hum of excitement, only to come face to face with your freshly finished dream car — gleaming under the lights, the culmination of patience, vision, and 5,500 hours of artistry. Hodess couldn’t stop smiling, and honestly, who could blame him?

Related posts:

- BMW Isn’t Done With The 8 Series Just Yet

- Christian von Koenigsegg Tells Us Why The Miata Is The Perfect Daily Sports Car

- Honda Just Jumped Into The Insurance Business

- Video: The Subaru BRZ Could Get A New Lease On Life, Even With Toyota Out Of The Picture

- Chevrolet Is About To Spill The Beans On The New ZR1’s Nurburgring Time

- New Tesla Roadster Could Use Banned F1 Tech

- New Range Rover Sport SV Is A Lightweight But A Heavy-Hitter

- If You Want This Full-Size Chevy Special, You’ll Have To Settle For A Four-Cylinder

- Max Verstappen and Chris Harris Tame the Wild Ford Mustang GTD on Road and Track

- Bentley’s EXP 15 Gives Us a Wild Glimpse Into Its All-Electric Future